BJ4020 - 報警器

1. ? ? Technical Parameter

Measuring condition

Part shall be measured under a condition (Temperature: 5~35℃, Humidity: 45%~85%R.H., Atmospheric pressure: 860 ~1060hPa) unless the standard condition (Temperature: 25±3℃, Humidity: 60±10%R.H. Atmospheric pressure: 860 ~1060hPa) is regulated to measure.

| 1 | Resonant Frequency | 3000 500Hz |

| 2 | Operating Voltage | 1 ~25 Vp-p |

| 3 | Rated Current | Max.5mA ,At 3KHz 50% duty Square Wave 3Vp-p |

| 4 | Sound Output at 30cm | Min. 89dB,At 3KHz 50% duty Square Wave 3Vp-p |

| 5 | Capacitance | 30000 ± 30% pF At 1KHz |

| 6 | Operating Temperature | -20 - +70℃ |

| 7 | Storage Temperature | -30 - +80℃ |

| 8 | RoHS | Yes |

| 9 | Weight | Approx ?15g |

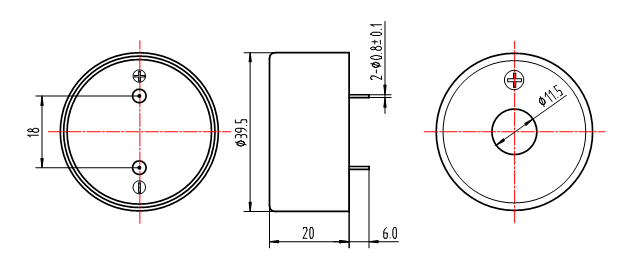

2. ? ? Dimensions

Unit: mm ? ? ? ? ? Tolerance: ±0.5mmExcept Specified

*Housing Material: Black ?PPO

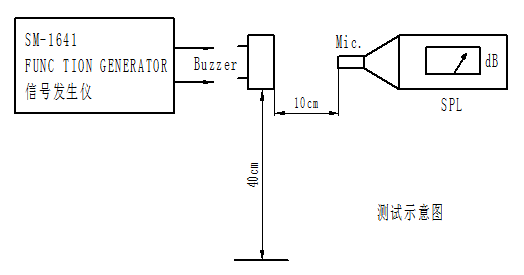

3.Electrical And Acoustical Measuring Condition

Recommended Setting

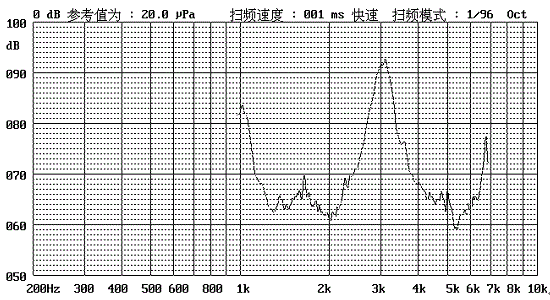

4.Frequency Response

3Vp-p 50% duty Square wave,30cm

5.ReliabilityTest

After any following tests the part shall meet specifications without any degradation in

appearance and performance except SPL. SPL shall not deviate more than -5 dB

from the initial value

5.1 Ordinary Temperature Life Test

The part shall be subjected to 96 hours at 25±10℃. Input rated voltage

Resonant frequency, 1/2 duty Square wave.

5.2 High Temperature Test

The part shall be capable of with standing a storage temperature of +80℃for 96 hours.

5.3 Low Temperature Test

The part shall be capable of with standing a storage temperature of --30℃for 96 hours.

5.4 Humidity Test

Temperature:+40℃±3℃ ? Relative Humidity:90%~95% Duration: 48 hours

and expose to room temperature for 6 hours

5.5 Temperature Shock Test

Temperature:70℃ /1hour→25℃/3hours→-20℃/1hour→25℃/3hours (1cycle)

Total cycle: 10 cycles

5.6 Drop Test

Standard Packaging From 1.2m(Drop on hard wood or board of 5cm thick,

three sides, six plain.)

5.7 Vibration Test

Vibration:1000cycles /min. Amplitude:1.5mm, Duration: 1 hour in each 3 axes

Note:

As this product is not protected from foreign material entering, please make sure that any foreign materials (e.g. magnetic powder, washing solvent, flux, corrosive gas) do not enter this product in your production processes. The functional degradation (e.g. SPL down) may occur if foreign material enter it.